Sparky Howard at the wheel of his sprinter, at San Jose (CA) Fairgrounds Speedway.

Photo (c) 1994 Steve Lafond, Tear Off Heaven Fotos

Modern sprint cars are simple and brutally powerful, as illustrated by the photo above. There is no dead weight on the car; if a part doesn't contribute to the car's performance, it is left off.

The chassis is a minimal tube frame with a short 84-inch wheelbase. The suspension, deliberately crude by modern standards, consists of a live axle in the rear and a dead axle up front, and torsion bars for springs. A V8 engine, fueled by methanol, is connected to the quick-change rear axle by a coupler called an "in-out box". There's no starter motor, and the battery is only large enough to power the ignition system for the evening. Two huge floppy rear tires of different sizes couple the irresistible force to the soft clay below. The driver sits atop the rear axle, his legs straddling the driveshaft.

With a power-to-weight ratio comparable to a Formula 1 racer's, and a short, tippy frame, a sprint car spends most of its time scrabbling for traction, broadsliding around the corners, wheelstanding on the straights, and throwing clay into the stands, while the driver wrestles frantically with the steering wheel.

In the golden era of the 1950s and early 1960s, the standard sprint car engine was the classic double-overhead-cam, 4-valve-per-cylinder, 4-cylinder Offenhauser. The 255-cubic-inch Offys made a low-pitched guttural roar that few who ever heard it have forgotten.

But during the 1960s, the Chevrolet small block V8 became popular. Originally these were cast-iron 283 and 327 cubic inch engines, with 2 valves per cylinder actuated by pushrods and rocker arms, little different from street Corvette motors of the era. As the racers searched for more power, the Chevy V8 was bored and stroked until displacements exceeded 400 cubic inches, and the iron castings gave way to purpose-built aluminum blocks and heads.

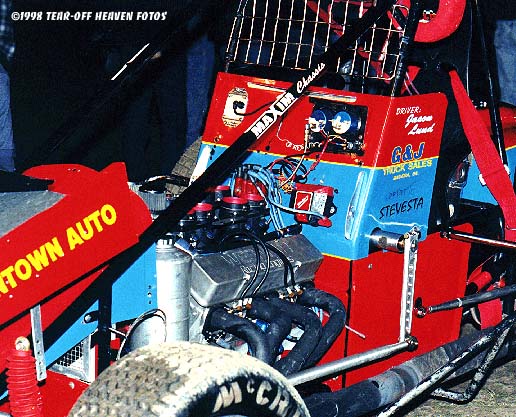

The standard powerplant of professional sprint car racing today displaces 410 cubic inches, and is based on alumimum blocks from Donovan or Rodeck, and aluminum heads from Brodix. The basic dimensions (bore center spacing, deck height, etc.) are still those of a Chevy V8, but you won't find a single GM part in the engine. Roller tappets and rocker arms actuate the titanium valves. Tall injector stacks top it off, feeding a potent mix of methanol and air to the cylinders. More fuel is injected through "down nozzles" in the side of the heads (see photo above). Oiling is handled by a dry sump system, with the oil tank often located just ahead of the driver on his left. These engines routinely top 8000 RPM, producing in excess of 800 BHP! The most potent of these engines are built by Ron Shaver and Earl Gaerte, whose motors power most of the winners on the World of Outlaws tour and regional series around the USA. These finicky machines require an overhaul after 8 to 10 evenings' work.

As with all else in sprint car racing, there are engines, and then there are Outlaw engines. To run with the Outlaws takes a little more motor than you'll find at most tracks. And even among the Outlaws, there are regular engines, and there are special engines built for the high-buck races like Eldora Speedway's King's Royal and The Big One (with $50,000 and $100,000 to win respectively), and sprint car racing's most prestigious event, the Knoxville (IA) Nationals. These expensive hand grenades are built extra hot, and may only survive one night's racing. But if they bring home the winner's prize, they're worth it!

In the 1980s, long-time team owner and Ford dealer Casey Luna became frustrated with the fact that he had to run a Brand X motor, and funded development of an aluminum sprint car engine based on Ford's potent 351 Cleveland V8. Like the "Chevy" engines, the "Ford" sprint car engine block and heads are actually cast by outside suppliers, usually Fontana or Alan Root.

In 1989 Luna finally achieved his goal of winning the World of Outlaws championship with this creation, with Bobby Davis Jr. driving. This was the year of the infamous World of Outlaws - United Sprint Association split, so some might question the validity of this trophy. But in 1996 Luna's Ford-powered sprinter won the title convincingly, with Dave Blaney at the wheel of the Vivarin #10, and no asterisks to be found anywhere!

More recently, Roush Yates Racing, famed for its NASCAR engines, has been building 360 cubic inch Fords for sprint car racing.

The fuel systems of these aluminum brutes deserve a closer look. Methanol has been used as a racing fuel in the US since 1927, because it offered an octane rating of around 114 when the gasoline of the day was only capable of 60 or so (that's where "Phillips 66" got its name, from its high octane rating!). The substantially higher compression ratios possible with methanol resulted in equally substantial horsepower boosts in the early days.

Modern racing gasoline has caught up on octane, but methanol has key safety advantages that keep it in the forefront of American racing. Methanol is easily diluted by water, making an alcohol fire easier to put out than a gasoline fire. And it burns cooler and more slowly than gas, which means it is easier on engine parts.

But methanol also has a lower energy density than gasoline, requiring almost twice the volume to feed the same size engine. It can be difficult to squirt enough fuel in through the intake ports! The down nozzles pictured above help quench this huge thirst.

This huge thirst also requires relatively large tanks. The typical sprint car carries a 30 gallon (US) tank -- and it's not unusual to see fuel stops in a 30 lap race if there have been several cautions!

Because the engine compartment is tight, many sprint cars mount the high pressure fuel injection pump behind the firewall, in the driver's compartment. This has obvious risks, especially when you consider that the driveshaft is directly below! Some years ago on a televised sprint car race, Gary Bettenhausen was burned when the driveshaft flew off and knocked off part of the pump, spraying fuel all over Gary and soaking his fire suit. Fire crews quickly extinguished the flames, but Bettenhausen's burns took quite a while to heal.

At US$25,000 or more, the price of competitive power is too steep for many who race sprint cars as a hobby. Tracks throughout the US have recognized this, and sanction races limiting engines to 360 cubic inches. In much of the US, this is the standard local formula.

Typical 360 rules are based on production cast-iron blocks and heads, using a wet sump in place of the expensive dry-sump system, and forbidding down nozzles. These restricted engines are typically much cheaper to build at around US$10,000. Some associations add further restrictions; the American Sprint Car Series rules are typical of many "spec head" series, head porting being one of the big expenses in building a competition engine.

These lower-priced engines have become popular with local racers, since the 360s can still crank out enough power to shower the stands with clay. Despite the lower power and increased weight, the 360-powered sprinters lack none of the excitement of their more expensive cousins. And on tighter or slicker tracks where traction is at a premium, 360s can run competitively with the 410s.

Another option in some sanctioning bodies is V6 power. USAC made V6 power legal some years ago when it appeared Detroit was going to phase out the V8 due to fuel economy concerns. While they were at it, USAC also gave the V6 a healthy weight break, so that V6-powered cars would have not only a competitive power-to-weight ratio, but a edge in cornering as well. V6-powered sprinters have won a number of USAC non-winged races on pavement. And Kurt Martin of Chico, CA reports that Mark Hall's #54 is a consistent winner on the Northern California 360 circuit with a 317 cubic inch Chevy V6. So these lighter, cheaper motors are a viable option on the smaller tracks.

Most sprint car racing today is done with a huge 5-foot-square (25 square foot) aluminum wing mounted atop the roll cage, and a 2-foot by 3-foot wing above the front wheels. The top wing's location can be adjusted by means of a hydraulic "slider", moving the aerodynamic center of pressure to compensate for changing track conditions.

Here again, some organizations attempt to limit costs by restricting the size of the wing, some ban hydraulic sliders, and some prohibit sliders of any sort.

Winged sprint cars started appearing at unsanctioned "open competition" races as early as the 1960s, and became wildly popular with fans throughout the US, over the objections of sanctioning bodies like USAC. Soon these "outlaw" racers were popular enough to form their own series, and the World of Outlaws tour was organized.

As in other forms of auto racing, the wings provide negative lift or "downforce" to help the car stick to the track. The large end plates also act like the feathers on a dart, helping the car stay pointed in the right direction and keeping it from getting too far sideways.

Another benefit of the end plates is the advertising space they provide for sponsors. This is especially important when you consider the difference between the cost of running a sprint car and the typical prize money at most tracks; no one makes a living on their winnings alone.

Most racers think the aluminum wing adds valuable crushable structure, cushioning the blow when a sprinter turns over. Many race drivers would gladly destroy a $500 wing to avoid a hospital stay!

There's no denying that winged sprinters are fast. The current lap record at Eldora Speedway, a heavily banked 1/2 mile clay oval in Ohio, is in excess of 120 MPH! Watching these cars run in humid air is an awesome sight, contrails following the racers down the straights, the engines straining and roaring against the aerodynamic load.

Monte Faccinto points Dennis Johnson's #14J into Turn 1 at the 1994

Pacific Coast Open at Kings Speedway.

But purists like me prefer our racing without wings. Not only do you get a better view of the driver at work, but the traction is harder to find. The cars get further sideways and spend more time sideways, putting a premium on driving talent and opening up a variety of different racing lines. Despite the slower lap times, many fans find non-winged sprint car racing offers more side-by-side action.

Winged cars require different engine tuning than non-winged sprinters. Downforce isn't free; the wing generates drag as well. The winged cars obviously require all the power the engine can deliver, limiting straightaway speeds. But the downforce means the cars can corner faster, so the average speed is much higher, and the engine tends to work in a fairly narrow powerband. At some tracks, under ideal conditions, the driver never has to back out of the throttle! Motors for winged cars tend to be tuned for maximum horsepower as a result.

The non-winged cars, on the other hand, lack the traction advantage of their winged cousins. And because the cars go slower in the corners, generate more wheelspin, and tend to be steered with the throttle more, smooth part-throttle response and controllability are often more important than maximum horsepower. Lealand McSpadden was quoted in an Open Wheel magazine interview as saying he couldn't apply full throttle until he was 3/4 of the way down the straightaway at some tracks. So engines for non-winged cars tend to have a wider operating range, broader torque curves, and often lower peak horsepower than those in winged sprint cars.

Page layout and text copyright © 1994-2016 Chuck Fry. Unless otherwise stated, all photos this page are by Steve Lafond, and are copyright © 1993-1998 Tear-Off Heaven Fotos.

See the full copyright notice for details.